machining surface finish grades

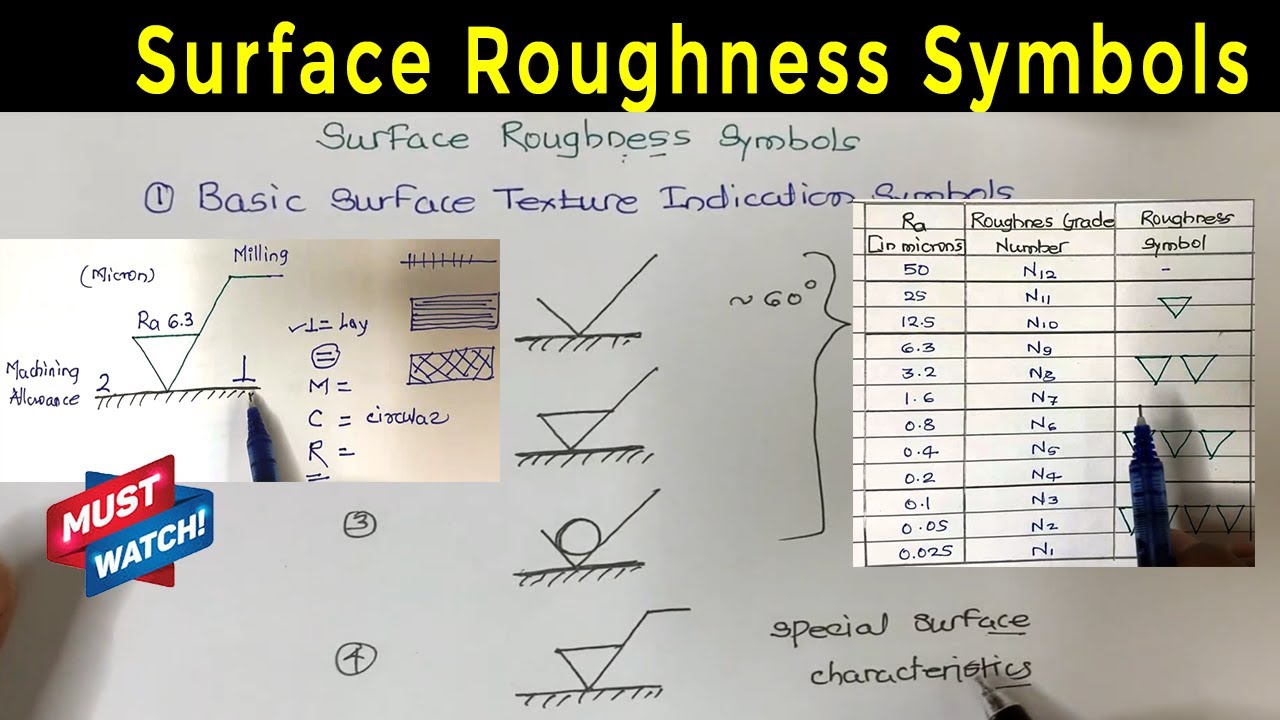

A scale between N1- N12 to designate. Ad Provides Enhanced Mechanical Properties Corrosion Protection.

5 Grinding Considerations For Improving Surface Finish Norton Abrasives

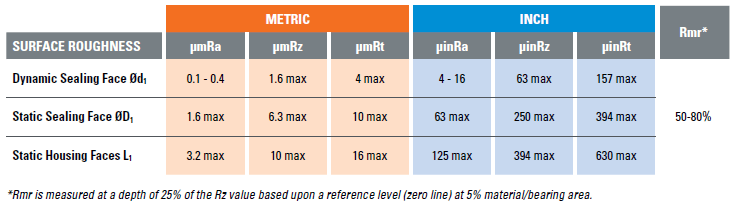

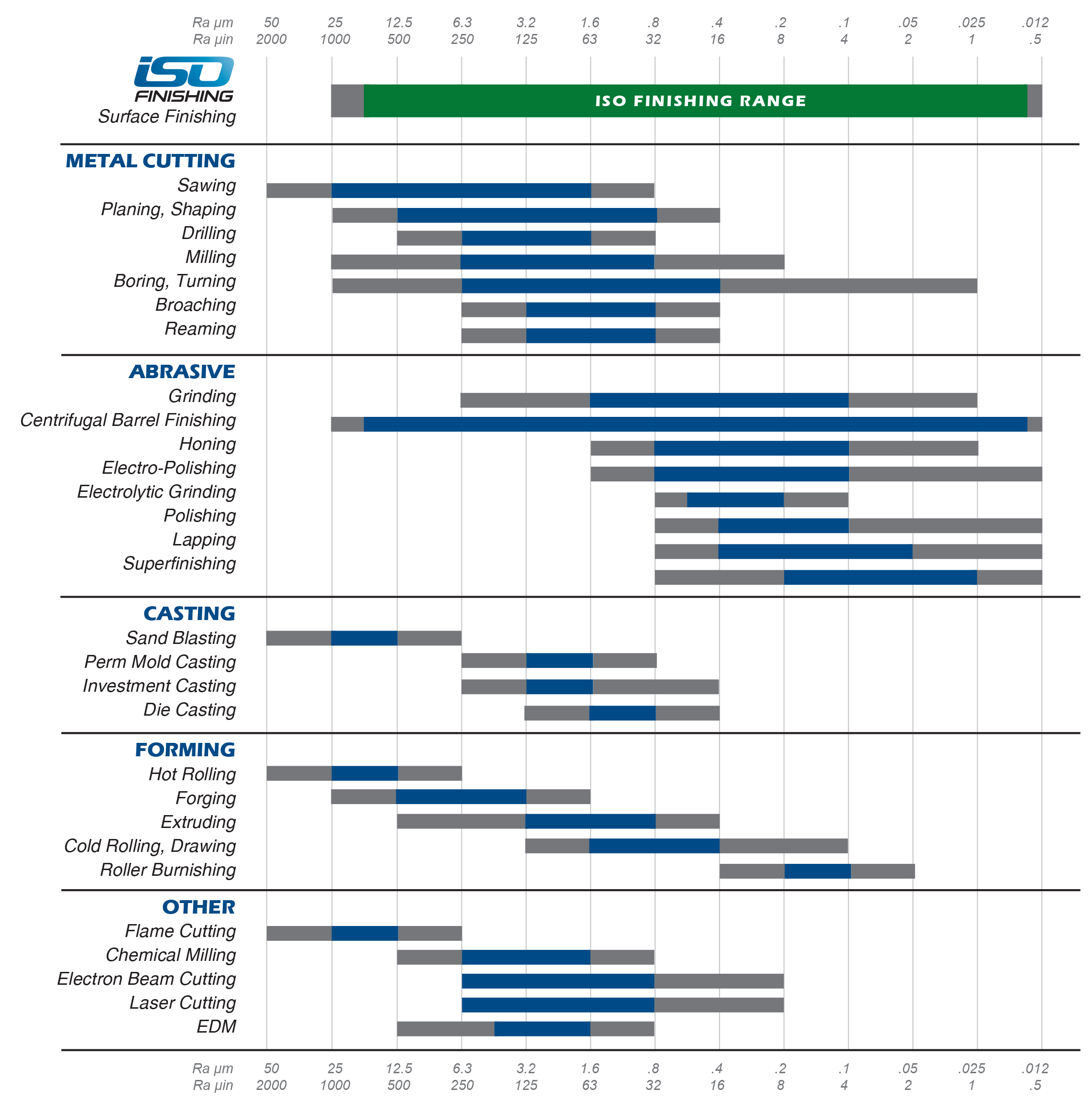

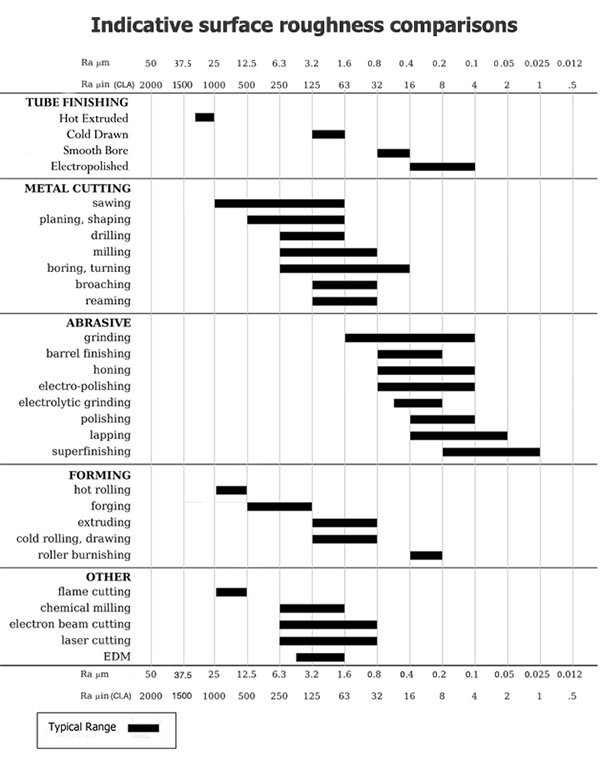

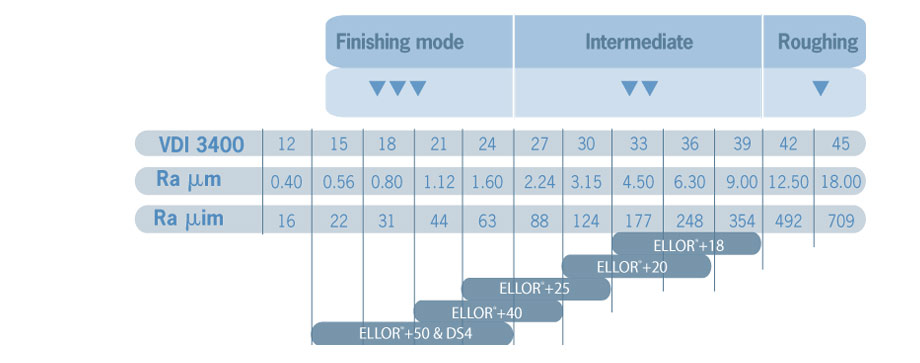

The following charts and tables convert surface finish or roughness between selected industry standard units.

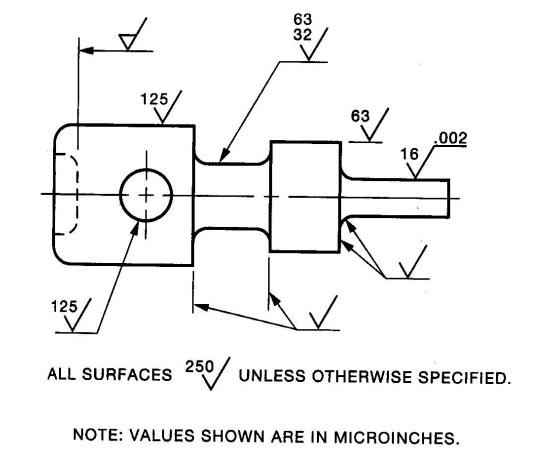

. Ra Average Surface Roughness. Surface Roughness Chart Symbols and Abbreviations. Up to 3 cash back fMachining symbols and Surface finish.

Surface Roughness Grades. Scientifically Proven to Give You a Competitive Advantage. Surface finishes may be increased to 16 08 to 04μm.

IATF 16949 Certified Facilities in USA Canada Mexico China Slovenia. The aim is to improve the functionality and aesthetics of these parts. As Machined parts have minor visible tool marks.

Ad Significantly Increase Productivity Reduce Costs in Just Minutes With Our New Service. Very large volume high precision 5-axis CNC milling and machine centers for heavy industry. Moreover imperfections on the surface material of the part are spot-polished or painted over.

While most people refer to Ra as Center Line Average or Arithmetic Average it is the average. Request a Test Today. This die casting surface finish may feature decorative coatings.

Ra Roughness average in micro-meters micro-inches. The most popular series numbers are 200 300 400 600 and 2000. Ad Electropolishing Oxygen Cleaning Passivating Polishing Services.

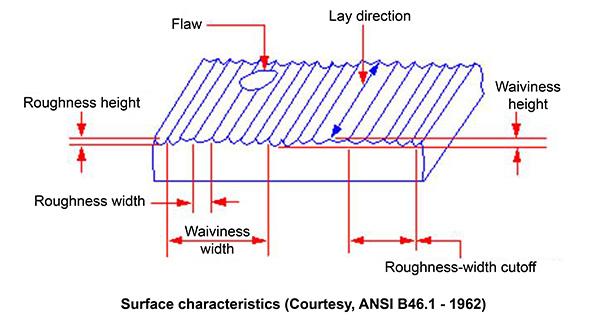

For steel parts below are the common. Surface finish is a parameter that determines the physical characteristics appearance of a component. Surface finish Also called sometimes surface roughness is a numeric representation.

Commercial Grade Typically this. 1 The machining accuracy during rough milling is IT11IT13 and the surface. This high-end surface finish necessitates meticulous attention to detail which adds to the expense.

Calculate FeedRate based on required Surface Finish 16 N ISO Calculated from Ra above Roughness grade number according to ISO 13021992. Ad Providing Quality Custom CNC Machined Components For Over 20 Years. It is a means of altering material surfaces through processes involving adding.

Measuring Surface Roughness Ra Surface roughness number Ra is expressed in microns. Surface finish requirements can be increased to 16 08 and 04 μm. 15 rows Machining N7 63 16 N8 125 32 Medium Machining N9 250 63 N10 500 125 Rough Machining N11 1000 25 N12.

Request a Test Today. Scientifically Proven to Give You a Competitive Advantage. Its essential for parts that are subjected to high levels of stress.

Bead blasting adds a uniform matte or satin surface finish on a. Ad Significantly Increase Productivity Reduce Costs in Just Minutes With Our New Service. Surface Roughness Grade Numbers Here is a chart shows how roughness grade numbers convert to Ra values and roughness symbols.

Ad Improve Cost Quality Of Critical Components With Precision Fineblanking. The machining accuracy of milling is generally up to IT8IT7 and the surface roughness is 6316μm. However different metals require different surface finishes.

Minorly visible tool marks with a standard surface roughness Ra of 32μm. Ra h1h2-----hnn The. The most common grades are type 304 and.

Surface Finish Surface Roughness Symbols Charts Callouts Costs

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Roughness Finish For Bearings And Seals Hallite

Surface Roughness Value An Overview Sciencedirect Topics

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

Surface Finish Gauges Testers Comparators Comparison Specimens Rubert Co Ltd

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish An Engineering Component May Be Cast Forged Drawn Welded Or Stamped Etc All The Surfaces May Not Have Functional Requirements And Need Ppt Video Online Download

What Are The Types Of Surface Finishes For Cnc Machining Hubs

Surface Roughness Chart Comparison Iso Finishing

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Experimental Lay Out Results For The Surface Finish Of Machining Aisi Download Table

Use Recommendations Mersen Usa World Leader In Isostatic Graphite For Edm

20 Typical Surface Finish For Basic Machining Operations Download Scientific Diagram